Automatic Roti Maker – Chapati & Roti Making Machine

This is the most compact, simplified & easy to use chapati-making machine available in the Indian market. All you need to do is to make the dough balls by hand, and then place them in the machine. The machine then takes care of the pressing and baking. The entire system is designed to ensure guaranteed satisfaction to the consumer along with 100% accountability of standardized mass production.

Home > Automatic Chapati Making Machine

Triple Conveyor Type

1 Export "SLIM" series

Model No – SS18 – 300 Roti/hr

- Model No: SS18

- Capacity: 300 Chapatis/Hr

- Type: Triple Conveyor Type

- Series: Export "SLIM" series

Model No – SS08 – 700 Roti/hr

- Model No: SS08

- Capacity: 700 Chapatis/Hr

- Type: Triple Conveyor Type

- Series: Export "SLIM" series

Model No – SS09 Slim – 1000 Roti/hr

- Model No: SS09 Slim

- Capacity: 1000 Chapatis/Hr

- Type: Triple Conveyor Type

- Series: Export "SLIM" series

Model No – SS10 Slim – 2000 Roti/hr

- Model No: SS10 Slim

- Capacity: 2000 Chapatis/Hr

- Type: Triple Conveyor Type

- Series: Export "SLIM" series

2 Premium "PRO" series

Model No – SS08 Pro – 700 Roti/hr

- Model No: SS08 Pro

- Capacity: 700 Chapatis/Hr

- Type: Triple Conveyor Type

- Series: Premium "PRO" series

Model No – SS09 Pro – 1000 Roti/hr

- Model No: SS09 Pro

- Capacity: 1000 Chapatis/Hr

- Type: Triple Conveyor Type

- Series: Premium "PRO" series

Model No – SS10 Pro – 2000 Roti/hr

- Model No: SS10 Pro

- Capacity: 2000 Chapatis/Hr

- Type: Triple Conveyor Type

- Series: Premium "PRO" series

3 Lightweight Do-it-Yourself "NEO" Series

Model No – SS19 Neo –300 Roti/hr

- Model No: SS19 Neo

- Capacity: 300 Chapatis/Hr

- Type: Triple Conveyor Type

- Series: Lightweight DIY"NEO" Series

Model No – SS20 Neo – 500 Roti/hr

- Model No: SS20 Neo

- Capacity: 500 Chapatis/Hr

- Type: Triple Conveyor Type

- Series: Lightweight DIY"NEO" Series

Model No – SS21 Neo – 1000 Roti/hr

- Model No: SS21 Neo

- Capacity: 1000 Chapatis/Hr

- Type: Triple Conveyor Type

- Series: Lightweight DIY"NEO" Series

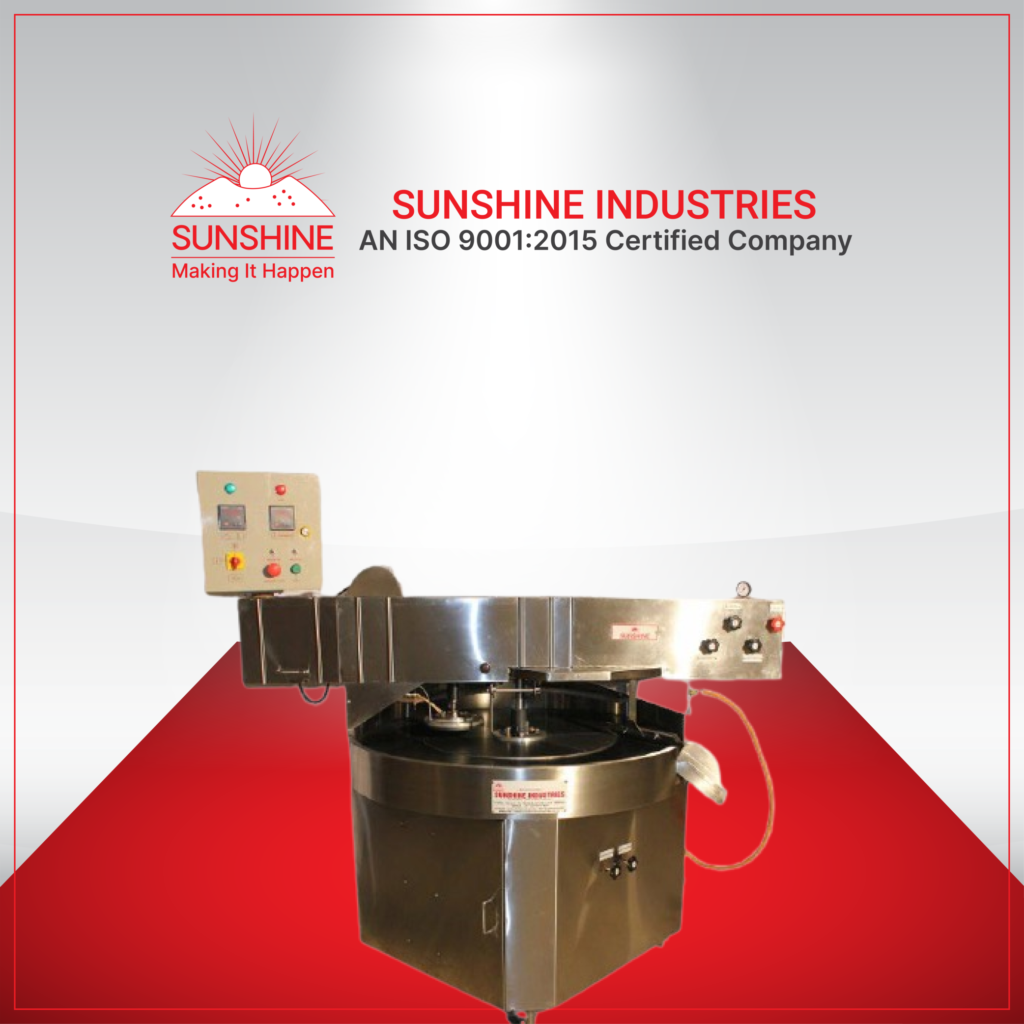

Wedge press rotary type

Model No – SS17 – 300 Roti/hr

- Model No: SS17

- Capacity: 300 Chapatis/Hr

- Type: Wedge Press Rotary Type

Model No – SS11 – 450 Roti/hr

- Model No: SS11

- Capacity: 450 Chapatis/Hr

- Type: Wedge Press Rotary Type

Model No – SS12 – 1000 Roti/hr

- Model No: SS12

- Capacity: 1000 Chapatis/Hr

- Type: Wedge Press Rotary Type

Welcome to Sunshine Industries – Leader in Roti & Chapati Machines

For more than 25 years, Sunshine Industries has been at the forefront of designing and manufacturing automatic roti and chapati making machines. What began in 2007 with our first commercial unit supplied to IIT Roorkee has now grown into a global legacy trusted by over 5000+ customers worldwide.

With 20+ machine models, cutting-edge R&D facilities, and certified quality systems, we are proud to offer complete chapati-making solutions—covering dough kneading, peda (dough ball) cutting, pressing, and baking. Whether you run a restaurant, hostel, canteen, hotel, or industrial kitchen, our machines are designed to make your chapati and roti production faster, hygienic, and cost-effective.

Automatic Roti Maker – Product Overview

The Automatic Roti Maker Machine is one of the most compact, simplified, and efficient roti-making machines in India. All you need to do is prepare the dough balls—our machine takes care of the rest:

✔ Pressing into uniform round shapes

✔ Baking with precise temperature control

✔ Puffing to deliver soft, home-like rotis

This process ensures standardized production, hygienic output, and consistent taste, meeting the needs of both small kitchens and large-scale commercial setups.

Types of Chapati / Roti Making Machines

Our machines are available in three major types, each designed to meet different production demands:

1. Triple Conveyor Type

The Triple Conveyor Roti Making Machine is known for its precision and productivity. It ensures uniform thickness and cooking with a smooth conveyor process, making it suitable for continuous mass production.

2. Wedge Press Rotary Type

This compact yet efficient model is perfect for medium-scale kitchens. It uses a wedge press with rotary motion to produce soft and evenly cooked chapatis or rotis.

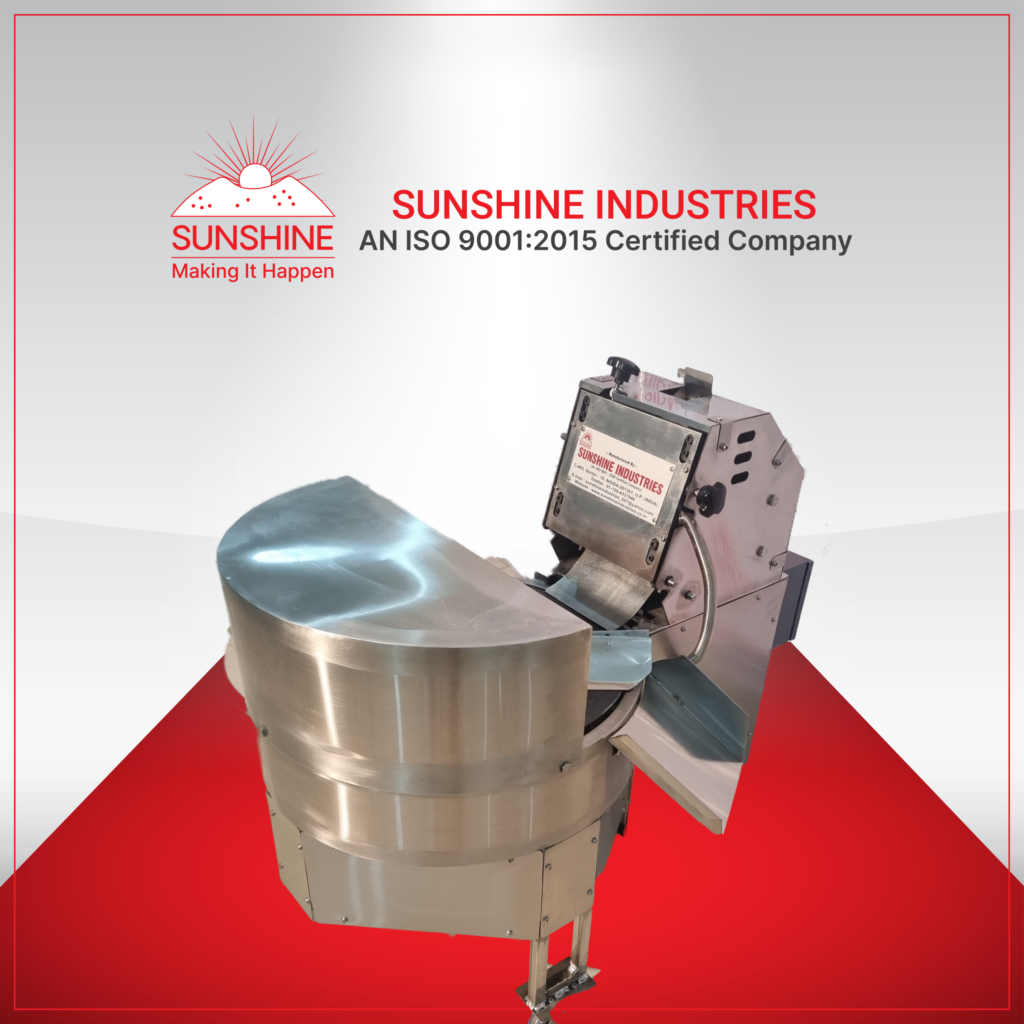

3. Rotary Indexing Type

The Rotary Indexing Roti Maker offers high-speed production with excellent consistency. Designed for industrial use, it ensures maximum efficiency and minimal manual intervention.

Key Features of Our Automatic Roti Machines

- Automatic Operation – Handles pressing and baking with precision for consistent rotis.

- Durable Build – Constructed with food-grade stainless steel for hygiene and durability.

- Energy Efficient – Uses advanced gas burners for baking with electric-powered pressing.

- Uniform Quality – Ensures every roti/chapati is evenly cooked and soft.

- Compact Design – Occupies minimal space, suitable for both small and large kitchens.

- Low Maintenance – Simple to clean and reliable for continuous heavy use.

- Safe & Hygienic – Designed to meet the highest food safety standards.

Complete Chapati-Making Solutions by Sunshine

We are not just roti machine manufacturers—we provide an entire ecosystem of chapati-making machines:

- Dough Kneading Machines – Uniform mixing & labor-saving

- Dough Ball (Peda) Cutting Machines – Precision-shaped pedas at high speed

- Chapati Pressing Machines – Standalone pressing solutions

- Fully Automatic Chapati Machines – End-to-end automation from peda to baking

This makes Sunshine a one-stop destination for businesses looking to scale chapati production.

Available Models & Specifications

We offer a wide range of models to suit different kitchen sizes and requirements.

Model No. | Capacity (Rotis/Chapatis per Hour) | Type | Best For |

SS18 | 300 | Triple Conveyor | Small restaurants, hostels |

SS08 | 700 | Triple Conveyor | Mid-size canteens, dhabas |

SS09 Slim | 1000 | Triple Conveyor | Large kitchens, catering |

SS10 Slim | 2000 | Triple Conveyor | Industrial kitchens |

SS17 | 300 | Wedge Press Rotary | Small-scale outlets |

SS11 | 450 | Wedge Press Rotary | Hostels, schools |

SS12 | 1000 | Wedge Press Rotary | Hotels, caterers |

SS02 | 1000 | Rotary Indexing | High-precision production |

With this variety, you can choose the machine that fits your production scale, budget, and kitchen size.

Benefits of Choosing Automatic Roti Maker

- Saves Time – Large batches in minutes, not hours

- Cuts Labor Costs – Reduces dependency on manual cooks

- Scalable – From 300 to 2000 rotis per hour

- Global Standards – Internationally recognized for durability & hygiene

- Versatile – Works for roti, chapati, phulka, and similar flatbreads

- Profitable for Businesses – High ROI for restaurants, hostels, and catering services

The Sunshine Legacy

- Founded in 2007, with first unit installed at IIT Roorkee

- Expanded into global markets in 2011

- 20+ product models catering to all kitchen sizes

- Known for innovation in design & performance

- Recognized as a top roti & chapati machine manufacturer in India

Our journey has always been about innovation + customer trust. Every product carries the Sunshine promise of quality, service, and long-term value.

FAQs Related to Roti Making Machine

As a trusted Indian manufacturer with 25+ years of experience, we deliver durable, high-performance chapati machines designed for Indian kitchens, backed by reliable service and pan-India support.

Our models range from 300 to 2,000 rotis per hour, making them suitable for operations of all scales.

Yes, we have dedicated models for hotels, canteens, hostels, and catering services.

Gas burners are used for baking, while electricity is used for pressing and operating motors.

Yes, Sunshine provides 24/7 service support, training, and maintenance guidance.

Primarily designed for rotis and chapatis, some models may accommodate thicker flatbreads depending on dough preparation.